At Portsmouth Aviation, we offer extensive testing and qualification services, which are carried out in-house whenever possible and by trusted partners. These processes ensure all of our products meet customers’ precise needs and are suitable for use in challenging environments.

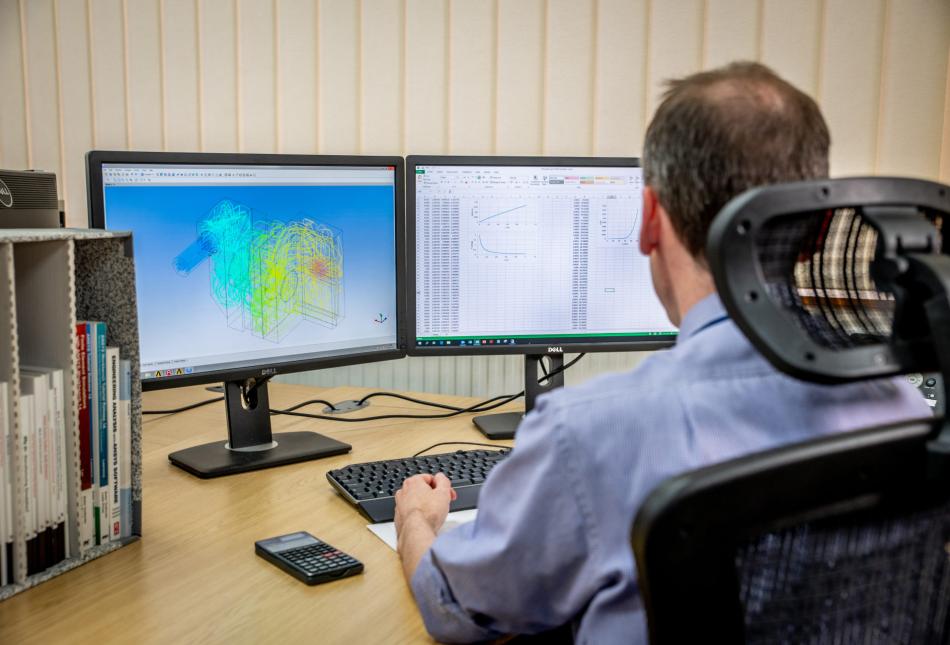

From the very first step in the design process, our engineers use state-of-the-art technologies, including FEA, to ensure that our products meet customer requirements.

FEA is the acronym for ‘finite elements analysis’ and it is a technique that uses computers to predict the behaviour of a variety of different types of physical systems such as deformation of solids, heat conduction and fluid flow.

In this article, we will look in depth at what Finite Element Analysis is, why and how it is used by the Stress Team at Portsmouth Aviation and what types of analyses are performed.

What is Finite Element Analysis and why is it used?

Finite Element Analysis (FEA) is the process of conducting structural or heat transfer simulations. This requires a computer to iteratively solve discrete, algebraic formulations of the governing equations (FEA) in order to calculate the structural or thermal responses for a specific loading scenario.

FEA is used to gain insight and calculate a structure’s response to multiple load cases and optimise a design before manufacture. Using FEA allows time and costs to be reduced as different designs can be analysed without needing to purchase materials and manufacture multiple designs for testing.

FEA allows you to get a more accurate result over analytical methods when the geometry is complex. It calculates parameters which are difficult or not possible to measure during testing due to safety reasons.

The FEA workflow is outlined as follows:

- FEA usually begins with a Computer Aided Design (CAD) geometry model (supplied by the Design Team), which is often simplified where appropriate. For example, deleting bolt holes and small components for a given analysis objective.

- The geometry is discretised into elements which are collectively termed a mesh. The equations are to be solved at the element nodes.

- Material properties, loads and constraints are applied to the mesh to represent real life load cases to be simulated.

- For structural assemblies the individual components are connected together using appropriate contacts or interactions.

- The computer then solves the equations using suitable numerical techniques to calculate the displacements, stresses, strains etc. throughout the model.

- Displacement, stress, strain etc. results are assessed using visualisations (e.g. contour plots, vector plots) and data (e.g. values of maximum, minimum, averages).

What FEA software does Portsmouth Aviation use?

At Portsmouth Aviation we use a software called Ansys. Ansys is an American company that develops and markets multi-physics engineering simulation software (FEA, CFD, Electromagnetics, etc.)

Ansys Elite Channel Partner EDRMedeso supplies Portsmouth Aviation with the latest Ansys products and technical support.

Portsmouth Aviation use Ansys® Mechanical for:

- Static/ transient and linear/non-linear structural analyses.

- Linear dynamics e.g., modal and vibration analysis with fatigue prediction.

- Explicit dynamics for highly non-linear, short duration scenario analysis.

In addition, Portsmouth Aviation uses Ansys® Fluent and Ansys® CFX for all fluid dynamic analyses ranging from external compressible aerodynamics to internal incompressible flows with porous media.

What are the benefits of using Ansys software?

There are a wide range of benefits to using Ansys software however the key points include:

- Ansys® Mechanical and Ansys® Fluent/CFX provide extensive and advanced physics models and solver methods.

- Easy to use interfaces and seamless analyses and file management using the Ansys® Workbench environment.

- Ansys® SpaceClaim geometry preparation software is included which also allows geometry creation independent of the CAD environment.

- Fluid Structure Interaction (FSI) is easily conducted by coupling Ansys® Mechanical and Ansys® Fluent/CFX within the Ansys® Workbench environment.

- Ansys® Mechanical and Ansys® Fluent/CFX analyses are scalable using High Performance Computing (HPC) for solving computationally intensive simulations.

Portsmouth Aviation’s use of FEA

Finite Element Analysis (FEA) was brought into Portsmouth Aviation Technical Office approximately 20 years ago as a tool to assist in the design process and was used for linear static structural analyses only.

Computational Fluid Dynamics (CFD), which is the fluid dynamics counterpart of FEA, was brought into the company 15 years ago for aerodynamics analysis and continues to be used for aircraft systems integration projects. CFD is routinely used in air filtration unit design and development.

The Ansys structural analysis capabilities were expanded beyond linear static structural analysis approximately 10 years ago due to the requirements of a new project at the time. These additional capabilities are now routinely used as required due to more demanding customer requirements.

Although FEA for stress analysis and CFD for fluid analysis are widely used tools within the Stress Office, analysis is not just about using these numerical software applications. The Portsmouth Aviation Stress Team also use a standard maths software and spreadsheets to conduct detailed analysis as well as specifying and conducting any physical testing that may be required for product development and qualification.

The Portsmouth Aviation Stress Team works in conjunction with the Design Team, by analysing designs as they progress through the conceptual, development and qualification phases to meet project requirements.

Find out more about the services we offer and the work we do. If you’d like to learn more about our FEA services, please get in touch.